In the supplier development literature, several researchers have recognised that strategic supplier development is important for the overall success of the firm and in turn contributes to a sustainable competitive edge and is considered one of the building blocks of supplier management practices. Authors like Wagner (2006a), Krause et al. (1998) suggested that it is important to identify, as part of a supplier strategy, which suppliers are ‘key’ suppliers and how they are to be treated differently. For example, it might be argued that strategic supplier development is only viable for ‘key’ suppliers and supplier switching might be an option for other suppliers. However, in the existing literature, there is a knowledge gap to understand specific suppliers’ motivations to participate in supplier development programmes and how buyers can influence suppliers who are not dependent upon them to participate in supplier training and technology/ product development.

Krause et al. (1998) have presented a differentiation between reactive and strategic supplier development, and have described a “reactive approach” that initiates actions only in cases of poor supplier performance and to eliminate existing deficiencies, i.e. when a supplier is not performing to the required standard and this can be classified as ‘fire fighting’ in nature. On the other hand, in the “strategic approach” firms try to improve supplier performance proactively and for the long-term capabilities to provide competitive advantage, i.e. before performance problems actually occur. Below Table depicts the major differences between strategic or systemic and reactive or remedial approaches to supplier development.

Difference between Reactive and Strategic Supplier Development

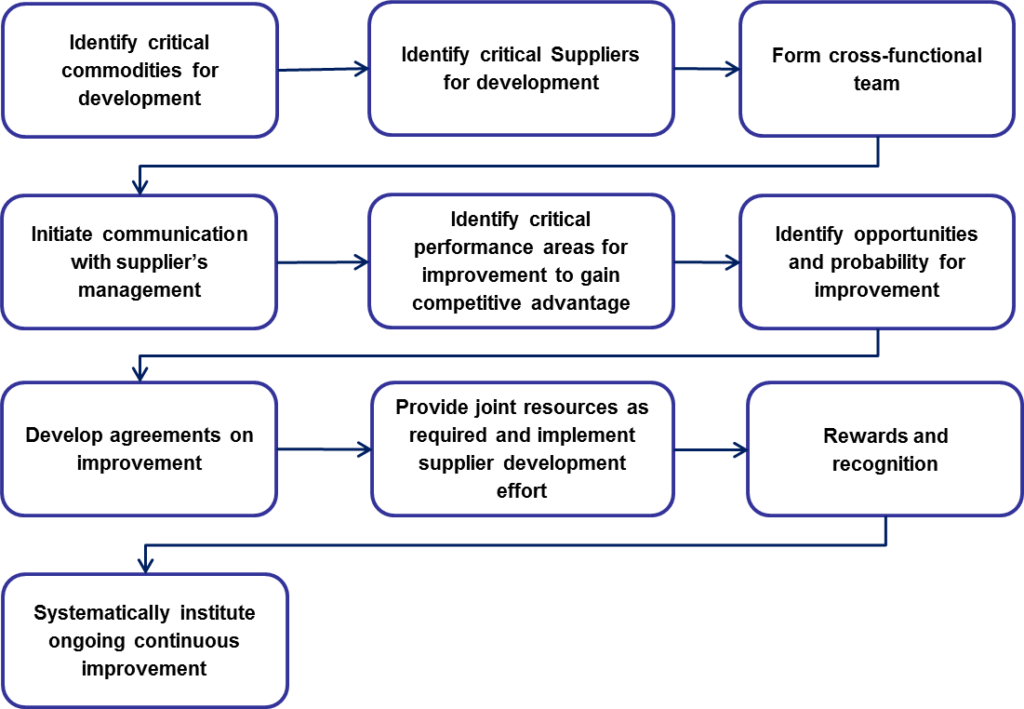

Krause et al. (1998) also suggested that firms tend to start using supplier development as a reactive tool and later use it as a strategic weapon when performance reaches adequate levels. This approach raises a question of whether reactive and strategic supplier development approaches can be used in tandem, which requires further research. The authors have also presented a generic ten-step process model using an inductive research approach. It starts with the identification of critical commodities for development to the systematic institution of ongoing continuous improvement, shown in Figure below.

|

Factors |

Reactive | Strategic |

| Primary Question | A supplier performance problem has occurred – what is needed to correct the specific problem?

|

We have dedicated resources to develop the supply base – where should resources be allocated for the greatest benefit? |

| Primary objective | Correction of supplier deficiency

Short term improvements

|

Continuous improvement of supply base

Long-term competitive advantages |

| Unit of Analysis | Single supplier

SUPPLIER DEVELOPMENT project |

Supply base

SUPPLIER DEVELOPMENT programme |

| Selection / Prioritisation Process | Supplier self-selects through performance or capability deficiency

Problem-driven |

Portfolio analysis Pareto analysis of commodity / suppliers Market-driven |

Table. Overview of differences between reactive and strategic SUPPLIER DEVELOPMENT

(source: Krause et al., 1998, p. 46)

Figure. Strategic supplier development process (source: Krause et al. 1998, p. 44)

In the existing literature it has been argued that strategic supplier development activities should focus on developing supplier future capabilities in product and technology development rather than just on current cost and quality issues Researchers insisted that developing future capability would be key for the long-term strategic success of supplier development.

However, research done by Reed and Walsh (2002) shows that there is little direct focus on technology in supplier development programmes and technology capability is a relatively low priority. Strategic supplier development was found to strengthen the relationship between customers and suppliers, which might enable both to disseminate technology road maps to each other, and suppliers are more likely to be involved in early product development.

There are a number of articles that have placed emphasis on linking the supplier development strategy with corporate purchasing strategy and business unit strategy and have mentioned supplier performance as an indicator to measure the result of supplier development These articles have determined that strategic purchasing has a positive impact on supplier evaluation systems, buyer-supplier relationships and firm’s financial performance.

In addition, it highlights the concept of corporate social responsibility and supplier development to develop a new approach, called socially responsible supplier development, to address suppliers’ ethical problems. However, during this review, no papers have been found showing a relationship between direct and indirect supplier development activities with reactive or strategic supplier development approaches; nor indicated the content of knowledge transfer while pursuing reactive or strategic supplier development. Thus, further empirical studies are needed to identify the specific relationship between direct and indirect supplier development activities with reactive and strategic approaches from the buyer company perspective.

Strategic supplier development program requires mutual recognition by the buyer and supplier. The selection of a supplier to be developed should be based on the supplier’s expectation of future joint cooperation and growth. When a supplier agrees to develop work on improvements of its capability and performance and expects to grow by dealing with the buyer, a strong strategic match should exist between buyer and supplier management, thus producing an alliance.

It is argued that supplier performance improvement and buyer’s competitive advantage should be used as the indicators to measure the result of strategic goals for supplier development programmes, but this provides a limited somewhat vague perspective of the performance outcomes of supplier development. Further study is recommended to present more specific valid measures of supplier development success in terms of short-term key performance indicators and measures of long-term relationship-specific and competitive advantage outcomes.

Antecedent Factors of Supplier Development

Many authors have investigated factors that precede or influence a firm’s decision to invest and become strategically involved in supplier development (Krause, 1999; Krause et al. 1998; Carr et al. 2008; Rogers et al., 2007; Wouters et al. 2007; Matook et al. 2009). The main antecedent factors relating to strategic supplier development found in this literature review are shown in Table.

| No. | Antecedent Factors | Authors |

| 1 | Buying firm’s top management recognition of purchasing importance | Krause (1999) |

| 2 | Continuous improvement | Krause et al. (1998) |

| 3 | Drive for rational efficiency (opportunity to improve supplier’s cost, quality, or service) and institutional image construction (the business environment where individual and groups continuously construct and maintain an appropriate image by taking data at its face value) | Rogers et al. (2007) |

| 4 | Importance of purchase input to the buying firm (strategic purchasing) | Carr et al. (2008) |

| 5 | Level of competition in the buying firm’s market | Krause (1999) |

| 6 | Overcoming resistance to change on the part of certain suppliers | Krause (1999) |

| 7 | Perception of the supplier’s commitment to the relationships | Krause (1999) |

| 8 | Supplier dependence on buyer | Carr et al. (2008) |

| 9 | Supplier integration into the buying firm’s operation | Krause et al. (1998) |

| 10 | Supplier risk management to create a viable supplier base | Matook et al. (2009) |

| 11 | Suppliers with rising spending power and rapidly developing economies | Wouters et al. (2007) |

| 12 | Supply chain optimization | Krause et al. (1998) |

| 13 | Technology and product development with key suppliers to achieve long term competitive advantage | Krause et al. (1998) |

| 14 | Value-added collaboration | Krause et al. (1998) |

Table . Antecedent factors relating to strategic supplier development

The main aim of these antecedent factors relating to strategic supplier development is to undertake improvements in the performance of first-tier suppliers through proactive strategic supplier development programmes. However, as discussed above, the literature lacks an operational framework on how to measure long term and short term supplier development success. In conclusion, four RGs have been identified in this literature review within the category of strategic and reactive supplier development.

Conclusion

Whilst there has been lot of work done to define reactive and strategic supplier development. There are few questions than still need to be answered:

- Investigate specific suppliers’ motivations to participate in supplier development programmes and how buyers can influence suppliers who are not dependent upon them to participate in supplier training and technology/ product development.

- Determine the relationship between direct and indirect SD activities with reactive and strategic approaches, from a buyer firm’s perspective.

- Investigate which supplier development practice and activities are best suited for supporting the firm’s product strategy i.e. cost leadership or differentiation strategy, hence contributing to a competitive advantage.

Let me know if you have answers of these questions!

References:

Krause, D.R., Handfield, R.B. and Scannell, T.V. (1998), “An empirical investigation of supplier development: reactive and strategic processes”, Journal of Operations Management, Vol. 17 No. 1, pp. 39-58.

Wagner, S.M. (2006a), “Supplier Development practices: an exploratory study”, European Journal of Marketing, Vol. 40 No. 5/6, pp. 554-571.

Reed, F.M. and Walsh, K. (2002), “Enhancing Technology Capability Through Supplier Development: A Study of the U.K. Aerospace Industry”, IEEE Transactions on Engineering Management, Vol. 49 No.3, pp. 231-242.

Recomended Reading:

Enhanced Supplier Development Framework: a systematic approach to improve supplier performance

Excellence in Supplier Management: How to Better Manage Contracts with Suppliers and Add Value – Best Practices in Supplier Relationship Management and Supplier Development (Excellence in…) (Paperback) – Common

Lean Supplier Development

About the Author- Dr Muddassir Ahmed

Dr MuddassirAhmed is the Founder & CEO of SCMDOJO. He is a global speaker, vlogger and supply chain industry expert with 17 years of experience in the Manufacturing Industry in the UK, Europe, the Middle East and South East Asia in various Supply Chain leadership roles. Dr. Muddassir has received a PhD in Management Science from Lancaster University Management School. Muddassir is a Six Sigma black belt and founded the leading supply chain platform SCMDOJO to enable supply chain professionals and teams to thrive by providing best-in-class knowledge content, tools and access to experts.

You can follow him on LinkedIn, Facebook, Twitter or Instagram