Category: Lean Six Sigma

Lean Six Sigma for SMEs: A Path to Continuous Improvement

In today’s fiercely competitive business landscape, the quest for continuous improvement has become imperative for small and medium-sized enterprises (SMEs) to thrive. Over the years,

Read More11 Best Lean Manufacturing Books to Read This Year and 2020

Are you finding it hard to understand Lean blogs and podcasts? One of the best resources to getting a full understanding of Lean is through

Read MoreWhat Types of Jobs Require Lean Six Sigma Green Belt Certified Professionals?

The Green Belt in the Six Sigma certification project is the starting point, after pursuing which, the candidates can go ahead to seek many other

Read MoreTop 15 Lean Six Sigma Books to Level Up Your Continuous Improvement Efforts & Strategy

For a business to maintain profitability and high-quality standard, owners and managers are required to level up and continuously improve both effectiveness and efficiency for

Read More5 Massive Reasons Why You Should Conduct 5S Kaizen in Your Business

Today’s business environment is ultracompetitive. Smart businesses are opting for better practices and operations that focus on eliminating waste, reducing costs, while also creating an

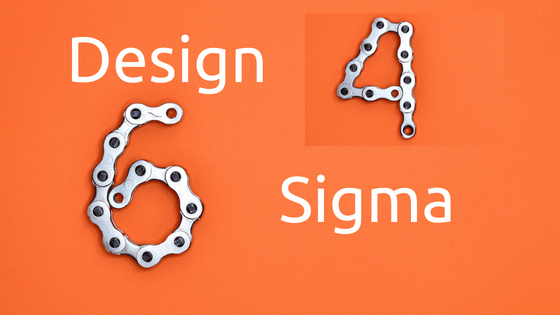

Read More11 Known Design for Six Sigma (DFSS) Methodologies

Design for Six Sigma (DFSS) is a product development approach that complements the Six Sigma problem-solving methodology. Promoted as “Six Sigma goes upstream,” Design for

Read MoreTop 13 Best Six Sigma Books and Courses For 2018

Several individuals believe six sigma books are difficult to comprehend. Yet, I believe six sigma books has transformed the operations management world in countless ways.

Read More10 Amazing Online Lean Six Sigma Courses for Supply Chain Professionals

Most supply chain professionals must be alert and quickly responsive to the changing needs of its customers. Modern-day Supply Chain Professionals are expected to be

Read More13 Operations Management Books Every Supply Chain Professional Should Read

There are so many different facets of Operations Management books recommended to every supply chain professional; it can be awe-inspiring when it comes to really

Read More11 Supplier Selection Factors to Establish JIT Supply Chain

In a JIT supply chain, reliable suppliers will reduce supply uncertainty and make the supply chain more effective, therefore supplier selection is crucial. However, Purchasing

Read More